Details

APPLICATION

WORKFLOW

PROCESS FLOW

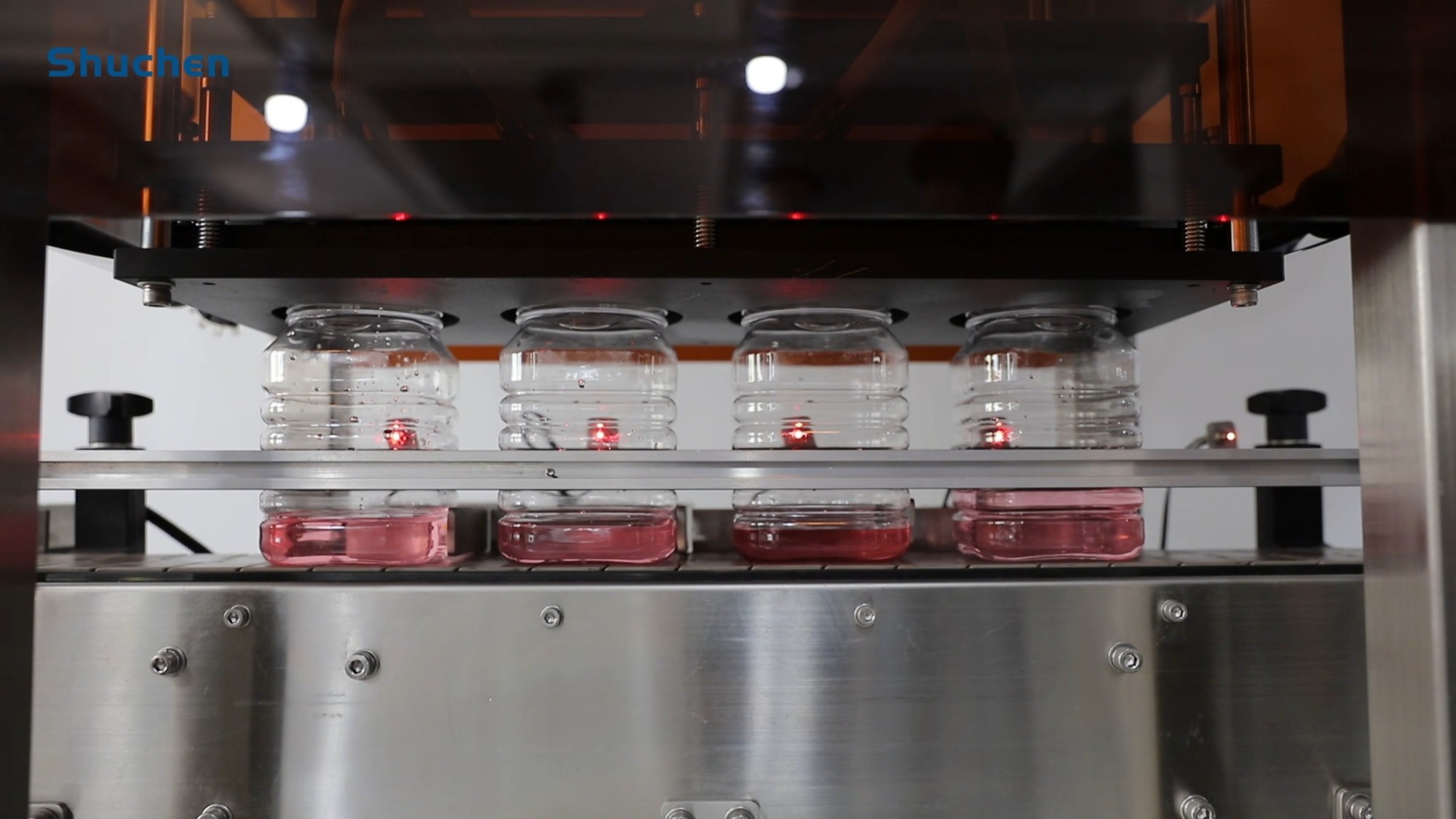

The bottles are fed into the mold via theconveyor belt → The film rollis automatically unwound → Automatic sealing and cutting → Automatically colle ct the wastefilm → Au to matic ally eject the bottles

SCOPE OF APPLICATION

●The assembly line one-to-four barrel and bottle sealing machine is widely used in various fields such as catering, food, health products,cosmetics, daily chemicals, pharmaceuticals, etc., and is applied to the packaging of products like alcohol, wet wipes, dried fruits, chopped chili peppers,etc.

●The frame of this machine is made of high -quality stainless steel and aluminum alloy.

●Electrical and pneumatic components alladoptinternatlonally renowned bra nds, ensuringstableworking performance.

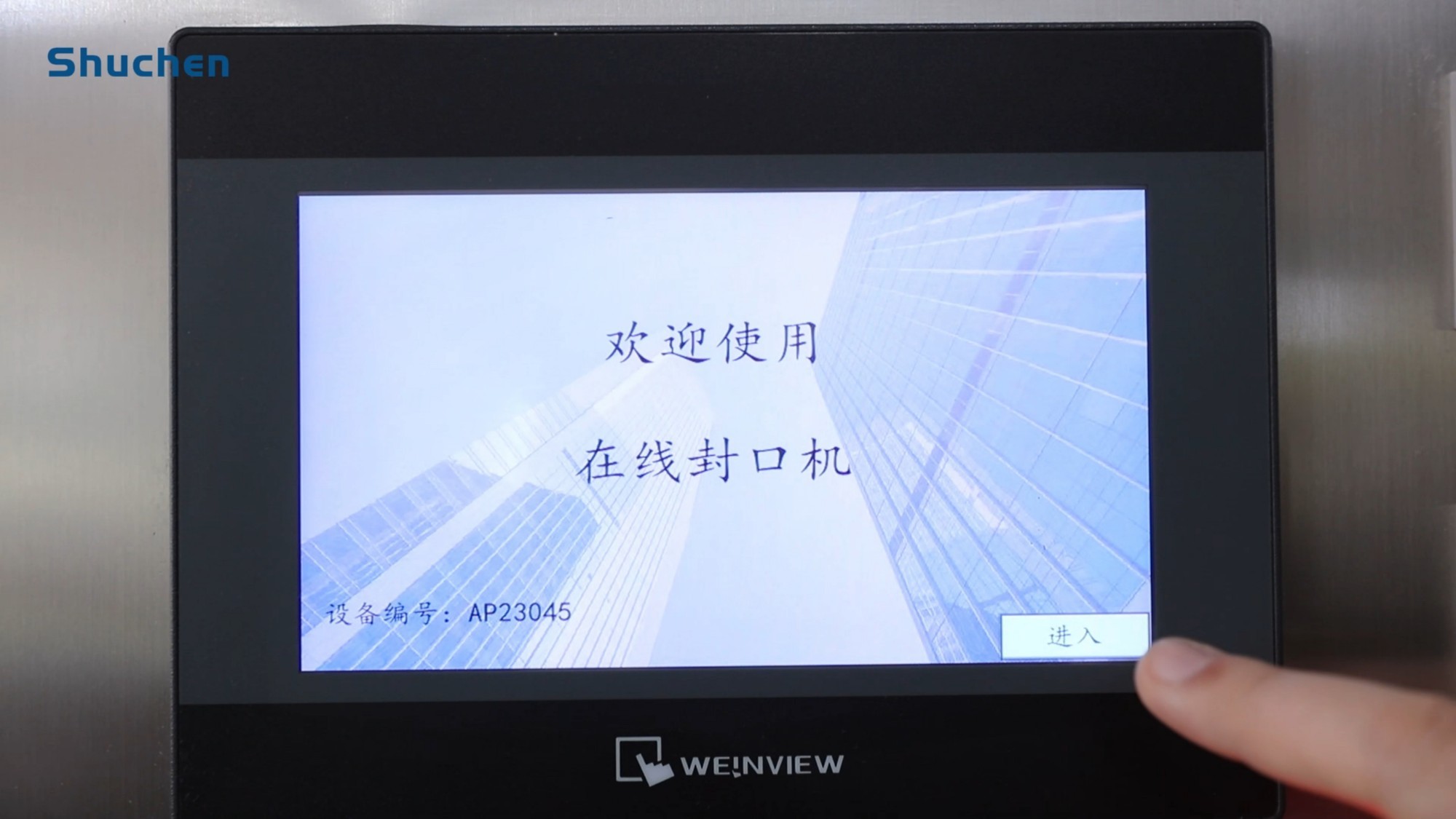

●Functions:The operationsoffeedingbottles bythe automaticconveyor belt,unwindingthefim roll,sealing,and outputting areallautomated.

●Custom -madenon - standard machines are supported.

TECHNICAL PARAMETERS

Machine type | JCL68-2 | JCL68-3 | JCL68-4 |

packaging speed | 800bottle | 1000 bottle | 1200bolttle |

Machlne voltage | 110V/220V/380V | ||

Machine power | 2KW | 2.5KW | 3KW |

Working pressure | 0.6Mpa | ||

Machlne slve | 2000*700*1600mm | 2000*700*1600mm | 2000*700*1600mm |

Machlne welght | 300Kg | 330Kg | 360Kg |

Related Products

Message

*Leave your contact information to get a free product quote