Details

APPLICATION

WORKFLOW

PROCESS FLOW

The equipment is suitable for packaging semi-liquid materials in the food, pharmaceutical, and chemical industries, such as honey, jam, chili sauce, vegetable oil, water, soy sauce, vinegar, dishwashing liquid, shampoo,

pesticides, etc.

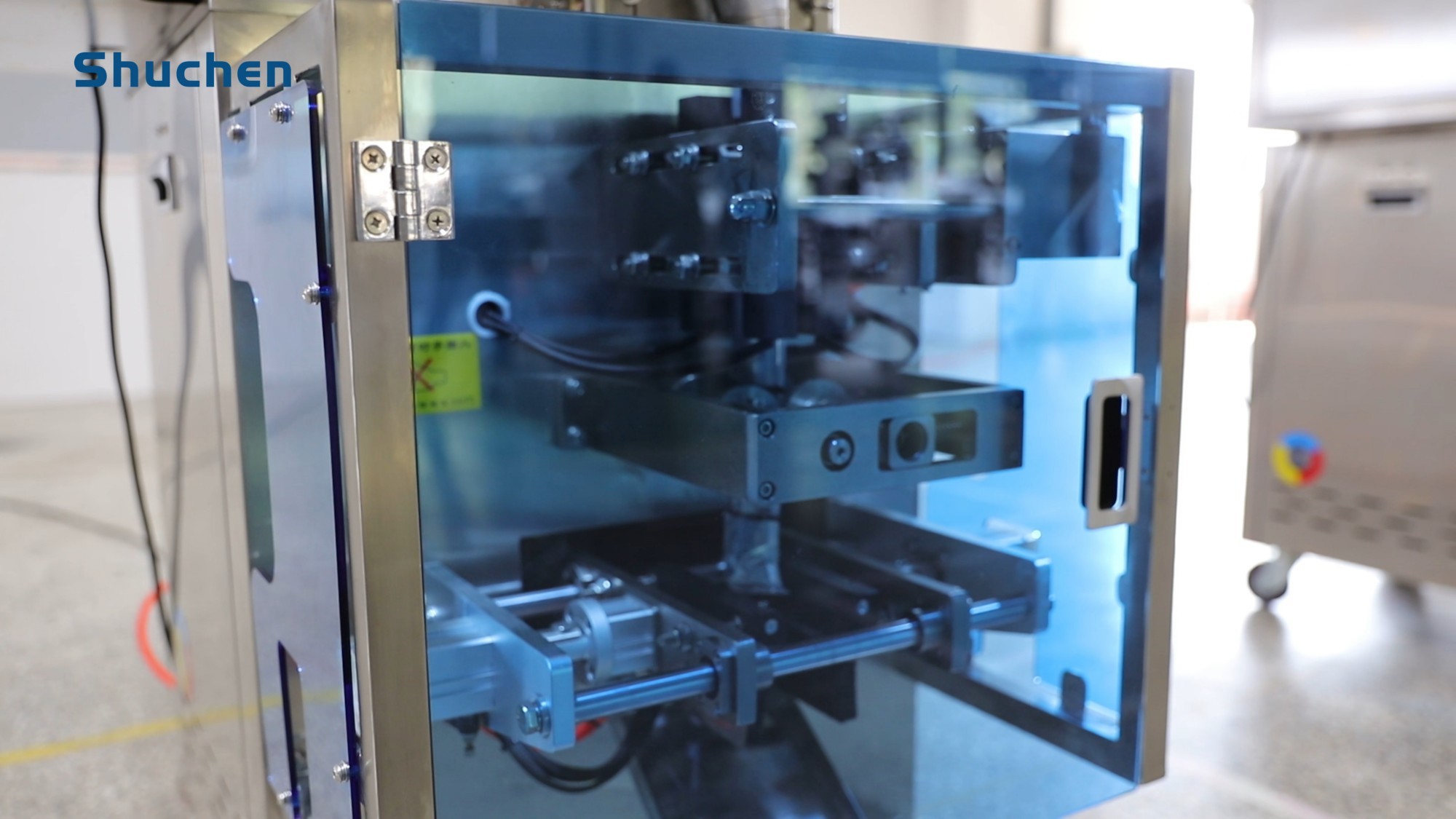

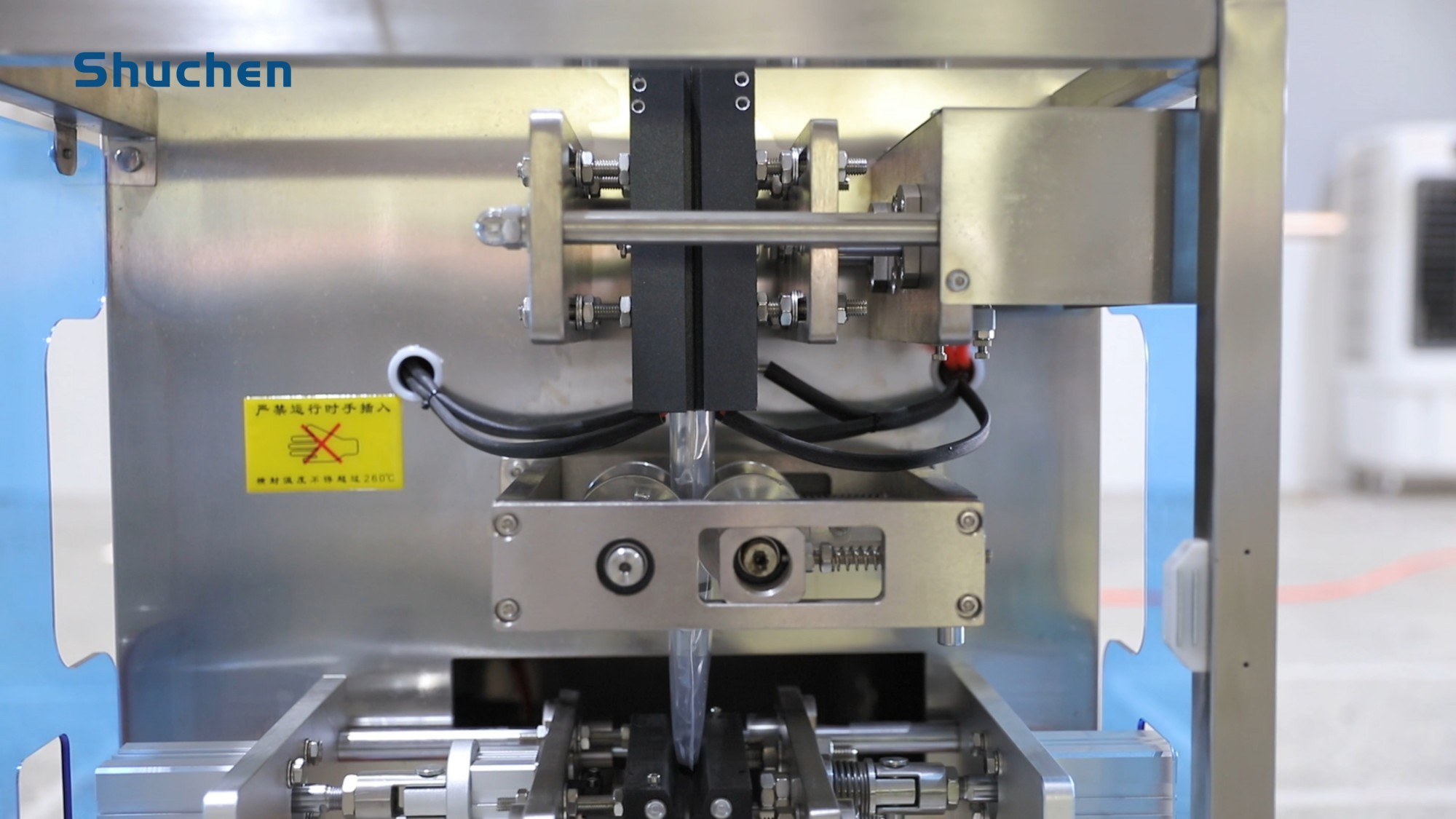

The machine features a microcomputer touchscreen interface for user-friendly operation. It can automatically complete bag forming, metering, filling, gas injection, sealing, cutting, counting, and coding

processes, and can be customized according to customer requirements. The intelligent photoelectric control system ensures complete bag patterns, while the metering system uses a piston volumetric pump for simple adjustment

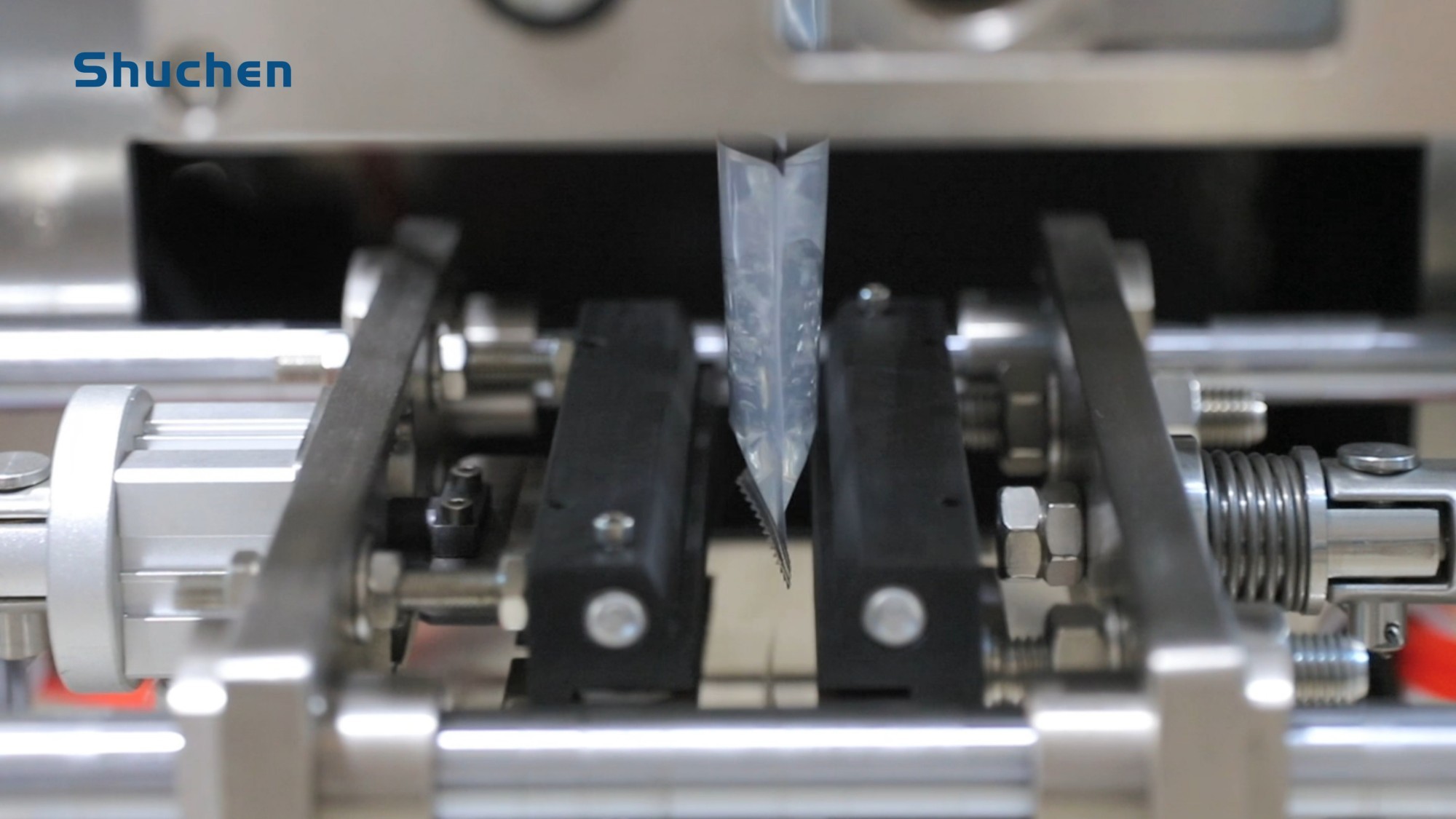

and accurate measurement; bag pulling is controlled by a stepper motor and color mark positioning, ensuring stable performance, easy adjustment, and accurate detection. This machine offers back sealing, three-side sealing, and four-side sealing packaging

options for customer selection. The cutting blade can be chosen in flat or serrated styles. The design ensures that this machine is suitable for various industries, with convenient adjustment, operation, and maintenance during use.

It can be used in conjunction with various automatic metering equipment from both domestic and international sources.

TECHNICAL PARAMETERS

Model | SJIII-S100 | SJII-S300 | H100DS(Vertical/horizontal barrel) |

Baglength | 50-150mm | 50-300mm | 50-170mm |

Bagwidth | 25-120mm | 70-190mm | 25-140mm |

Packingfilm width | 50-260mm | 140-380mm | 50-280mm |

Packaging capacity | 5-100ML | 100-1000ML | 5-100ML |

Packagingspeed | 30-50bags/min | 20-40bags/min | 10-65bags/min |

Power | 1.6KW/220V/5OHZ | 1.8KW/220V/50HZ | 1.5KW/220V/50HZ |

Gas source | 0.8Mpa | 0.8Mpa | 0.8Mpa |

Airconsumption | 150L/min | 250L/min | 200L/min |

Weight | 300Kg | 500Kg | 200Kg |

Related Products

Message

*Leave your contact information to get a free product quote