Details

APPLICATION

WORKFLOW

PROCESS FLOW

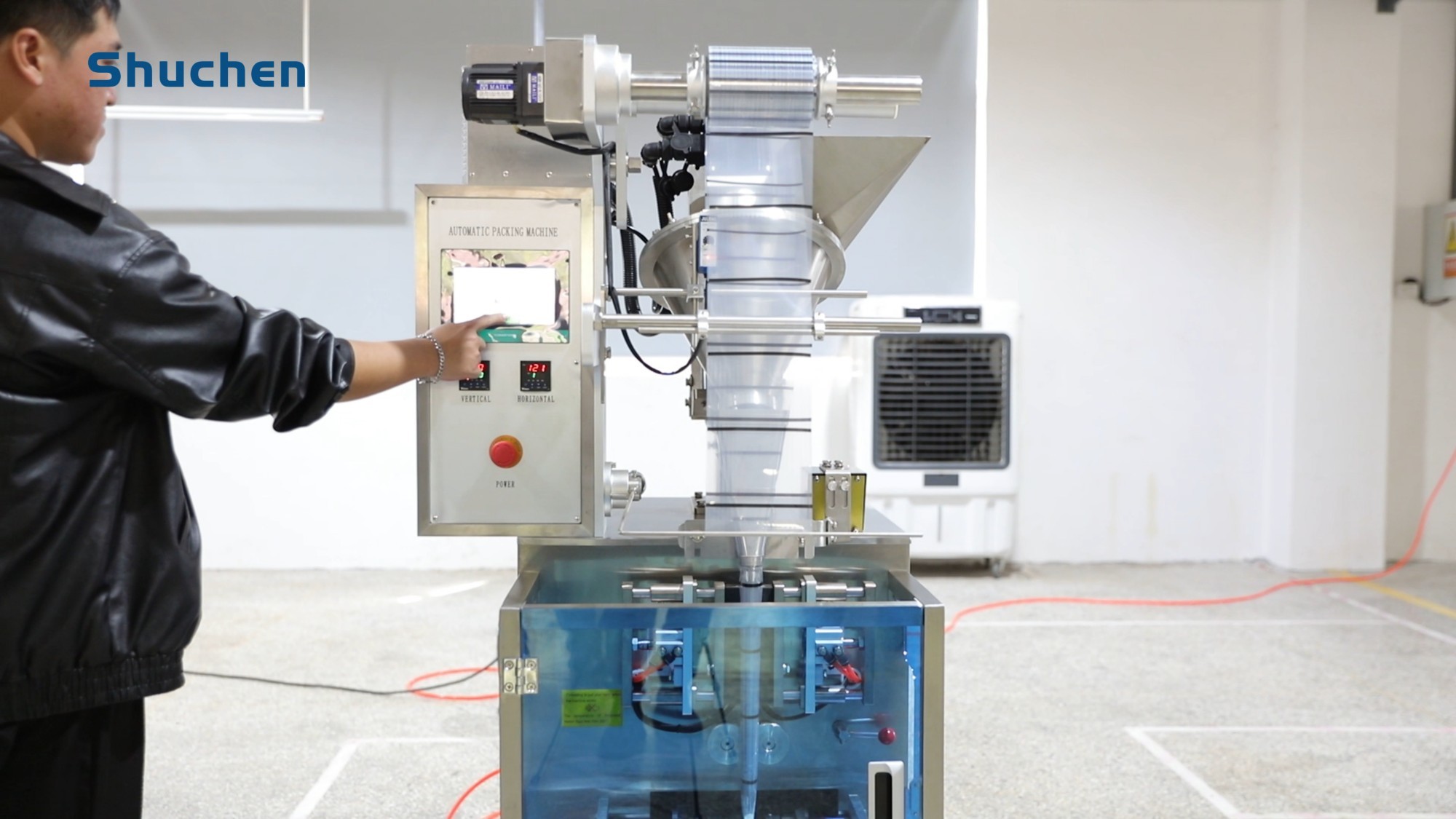

Suitable for powdered materials used in food, pharmaceutical, and chemical industries, such as flour, soybean powder, seasoning powder, coffee powder, food additives, etc. This machine features a fully computerized touchscreen interface, offering a user-friendly and convenient operating experience. It is equipped with an internationally renowned PLC control system, capable of automatically completing bag forming, metering, filling, gas injection, sealing, cutting, counting, and coding. Additionally, it can be customized according to customer requirements.

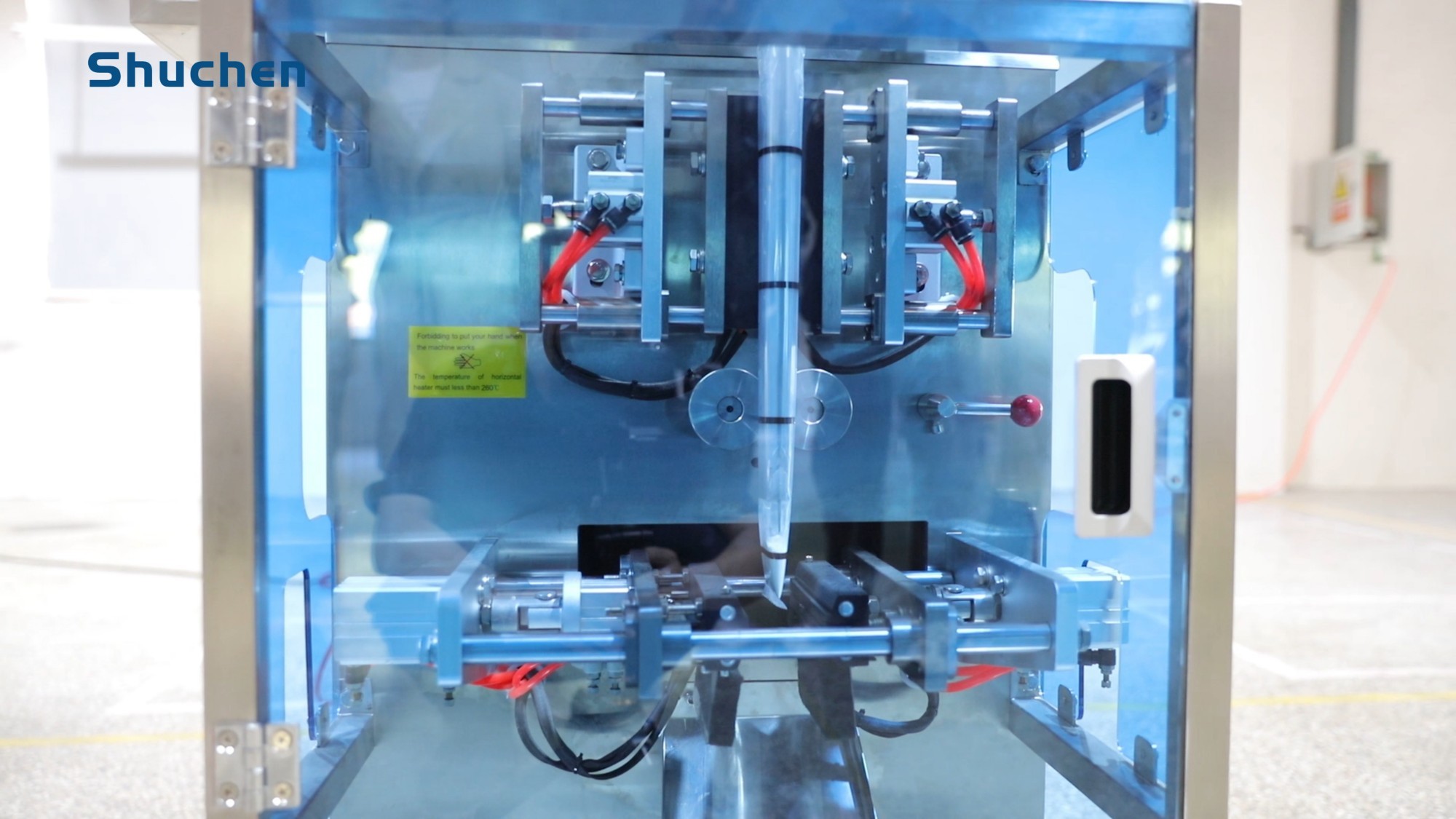

The filling and metering system is equipped with a servo drive motor, enabling program-controlled automatic operation with high torque, stable performance, and precise measurement. It also features a photoelectric control device to ensure the integrity of the packaging bag patterns. The bag pulling mechanism is controlled by a stepper motor with color mark positioning, offering stable performance, convenient adjustment, and accurate detection. The material feeding method is selected based on material characteristics, with sealing options including three-sided, four-sided, or back sealing. The design ensures the machine is suitable for various industries, with convenient adjustment, operation, and maintenance. It can be used in conjunction with various automatic metering equipment from both domestic and international sources.

TECHNICAL PARAMETERS

Model | SJIII-F100 | SJIII-F300 | H100DF |

Bag length | 50-150mm | 50-290mm | 45-170mm |

Bag width | 25-120mm | 70-190mm | 25-140mm |

Packingfilm width | 50-260mm | 140-380mm | 50-280mm |

Packagingcapacity | 5-100ML | 100-1000ML | 5-100ML |

Packagingspeed | 30-50bags/min | 20-40bags/min | 25-80 bags/min |

Power | 1.8KW/220V/50HZ | 2KW/220V/50HZ | 1.8KW/220V/50HZ |

Gas source | 0.6Mpa | 0..6Mpa | 0.8Mpa |

Air consumption | 100L/min | 100L/min | 200L/min |

Weight | 300Kg | 500Kg | 247Kg |

Related Products

Message

*Leave your contact information to get a free product quote