Details

APPLICATION

WORKFLOW

PROCESS FLOW

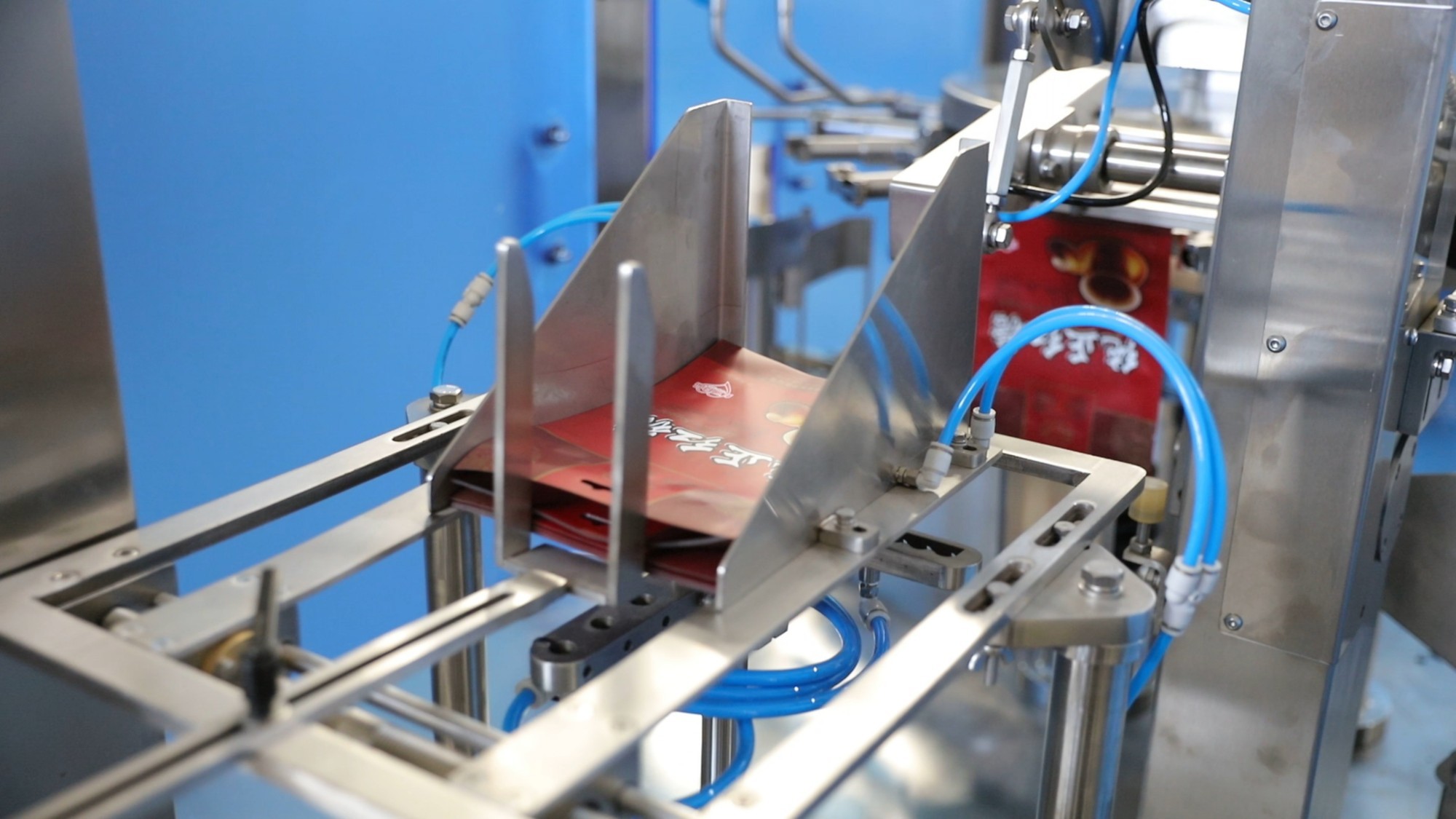

The entire machine's food contact surfaces are made of 304 stainless steel, meeting the hygiene standards of the food processing industry. It features PLC control with a color touchscreen display, allowing parameters such as packaging quantity and packaging accuracy to be set directly on the screen, ensuring simple operation. The dual synchronous drive system ensures precise bag dosing. The machine automatically completes the following processes: bag loading, printing, bag opening, filling, compaction, sealing, shaping, and output.

The liquid and paste metering packaging system consists of a rotary packaging machine and a liquid filling machine, equipped with an internationally renowned PLC control system. Imported electrical components and original parts are used to ensure

equipment quality and stable operation. A waterproof system facilitates cleaning. Stable performance, high speed. Automatic detection function: if the bag is not opened or opened incompletely, no material is added, and no heat sealing is performed, allowing the bag to be reused and avoiding waste, thereby saving production costs for users; safety device: when the working air pressure is abnormal or the heating tube malfunctions, an alarm is triggered; adjusting the bag width is controlled by a motor, and pressing the control button allows adjustment of the width of each group of clamps, making operation convenient and saving time.

TECHNICAL PARAMETERS

Model | HL8D-250S |

Type of packaging bags | Self-supportingbags,handbags,zipper bags,four-sided bagthree-sided bags,paper bags and other composite bags |

Packing bagsize | W:50-250mm L:80-350mm |

Filling area | 10-1500g |

Packagingspeed | 25-60 bales/min (the speed is determinedby the produc itselfand thefilling weight) |

Packagingaccuracy | Average accuracy≤±1% |

Total power | 3.5KW |

Scope of application | Peanut pulp,jam,chili sauce,detergent,rice wine,soysauce,ricevinegar,fruitjuice,etc |

Metering equipment | LUiquid[sauce]meter |

Workflow | 1.Bagging2.Printing productiondate 3.Baging4.Cutting5 Heat Seal6.Shaping andOutput |

Related Products

Message

*Leave your contact information to get a free product quote